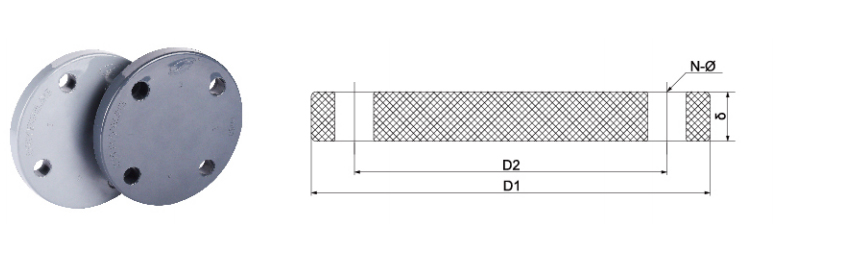

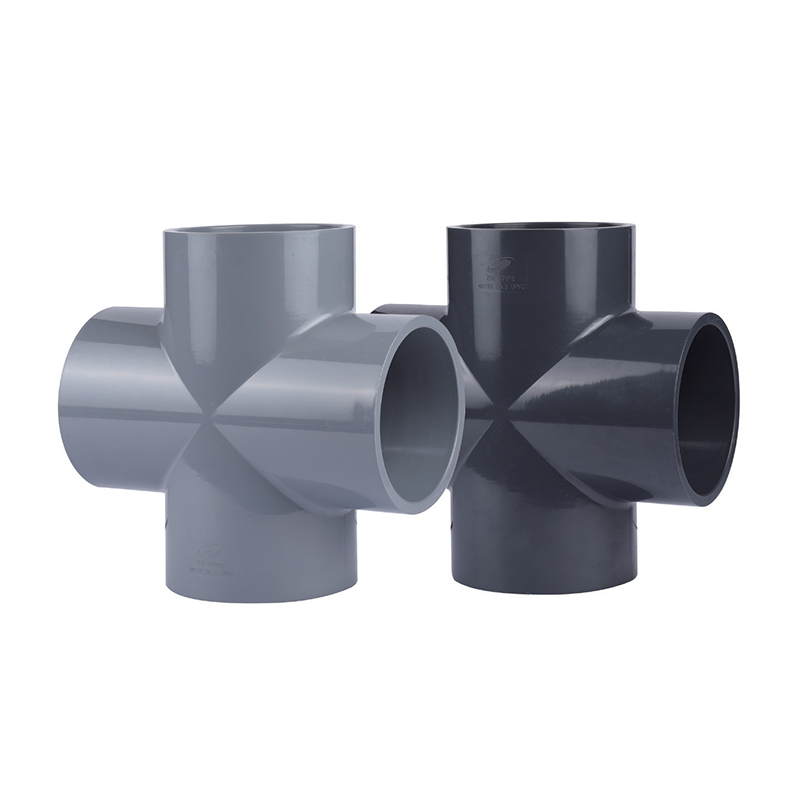

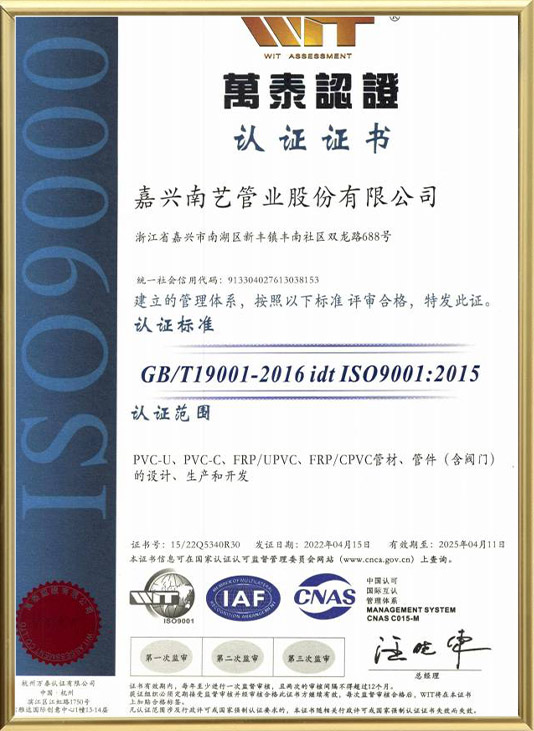

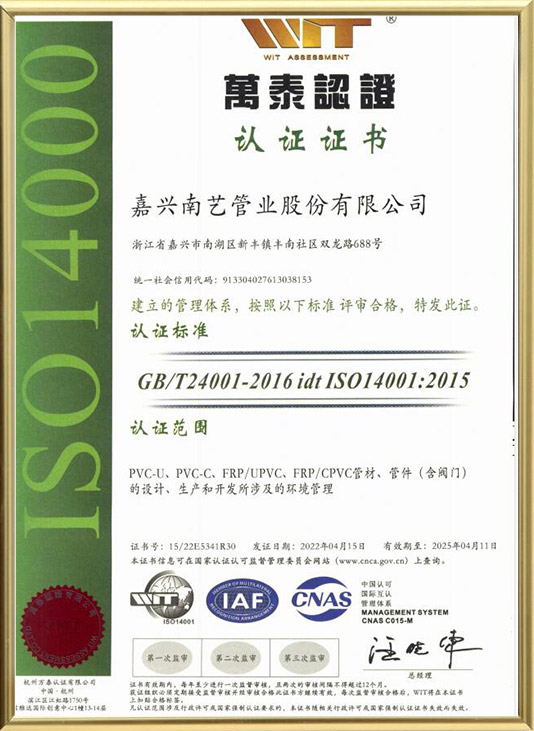

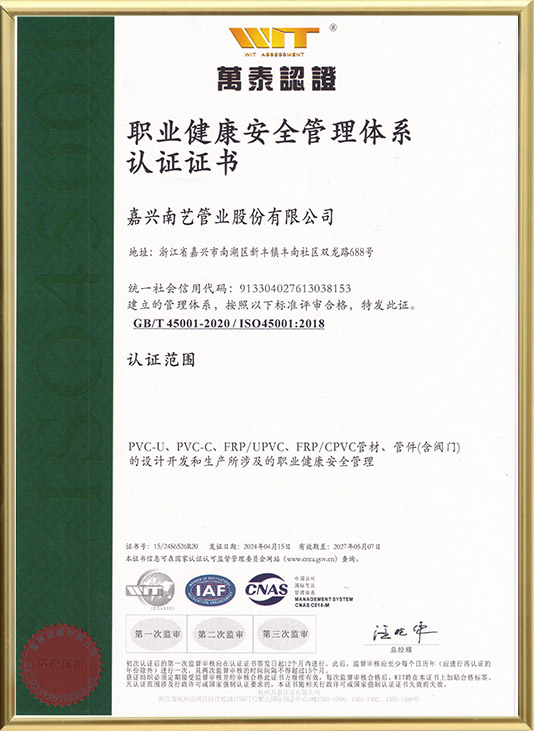

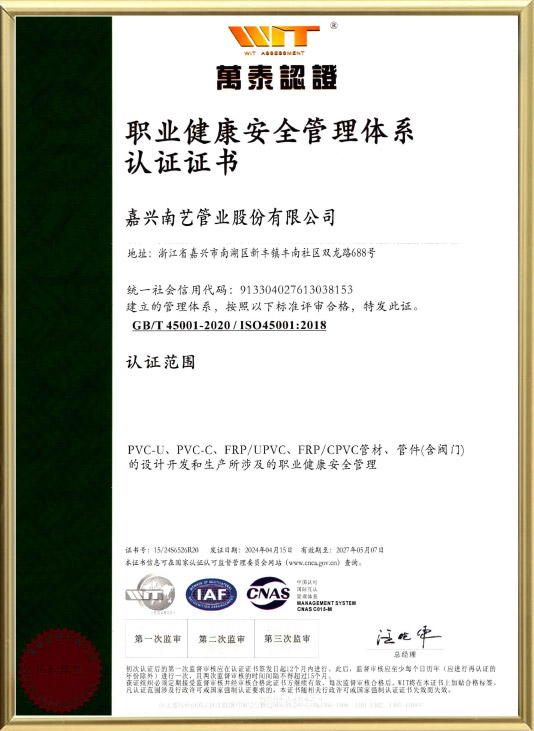

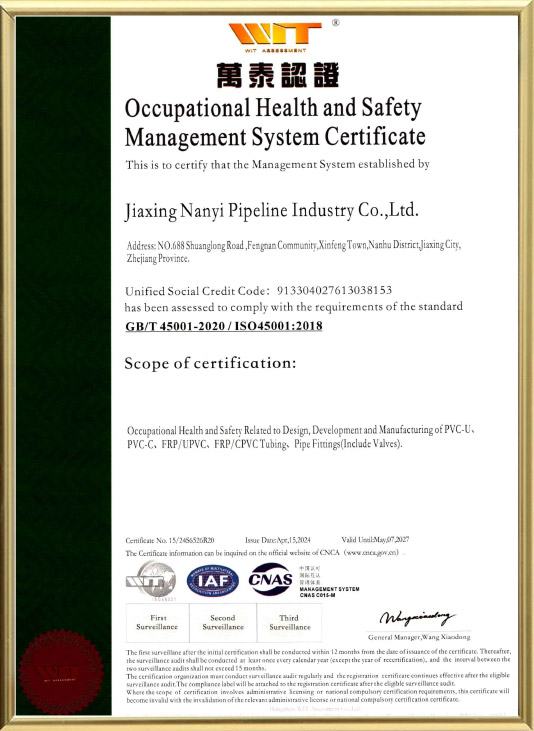

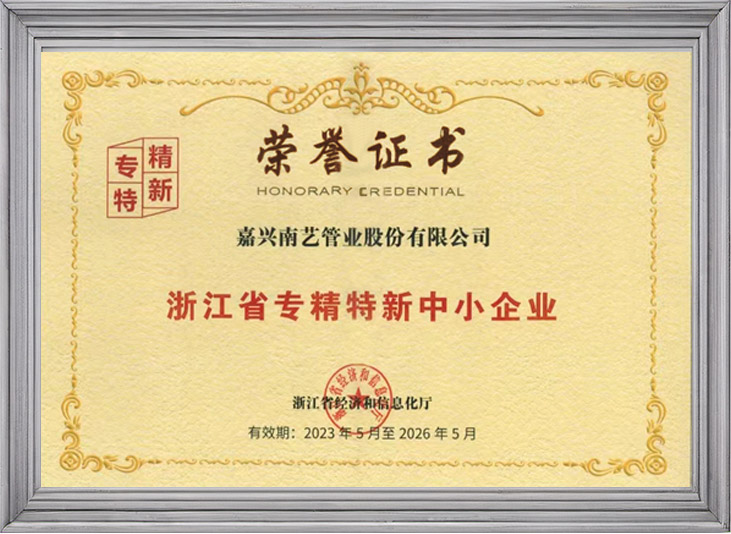

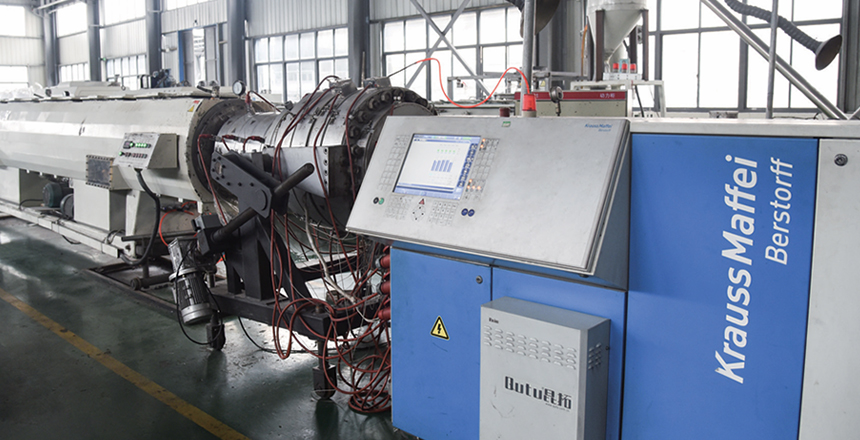

ZHEYI Group ja Kina SCH8O/DIN UPVC/CPVC Blind Flange För livsmedelsindustrin/fordon/elektronisk leverantör och specialtillverkad SCH8O/DIN UPVC/CPVC Blind Flange För livsmedelsindustrin/fordon/elektronisk fabrik. Vi grundades 2007 och fokuserar på forskning och utveckling, tillverkning, försäljning och service av industrirör av CPVC och UPVC. Företaget har erhållit ett antal certifieringar, inklusive produktionslicens för specialutrustning, hygienlicens för vattenrelaterade produkter i Zhejiang-provinsen, IS09001-certifiering för kvalitetsledningssystem, IS014001-certifiering för miljöledningssystem och IS045001-certifiering för arbetsmiljö och säkerhet. Företaget har mer än 50 oberoende immateriella rättigheter och egenutvecklade import- och exporträttigheter. För att kunna erbjuda diversifierade produkter och bättre tjänster har företaget introducerat avancerad teknik, verktygsutrustning och unika råvaror och ledningssystem från Tyskland och USA. Under årens lopp har våra produkter använts i stor utsträckning för rörledningstransport av syra- och alkalivätskor, ultrarent vatten, dricksvatten, rent vatten av elektronisk kvalitet och industriellt avloppsvatten inom kemi, metallurgi, solceller, kärnkraft, litiumbatterier, elektroniska halvledare, livsmedel, medicin, bilindustri, industriell vattenrening och andra industrier. För närvarande har ZHEYI Group etablerat mer än 30 försäljningsbolag över hela landet, och alla typer av produkter exporteras till Europa, Amerika, Sydostasien och andra länder och regioner, och är djupt gynnade av inhemska och utländska kunder.

Översikt över CPVC-kulventil med fläns Applikationer och installationskrav Den CPVC-kulventil med fläns används ofta i industriella rörledningssystem som hanterar frätande vätskor, vätskor med hög ren...

Läs mer +86-15258772971

+86-15258772971

dinys009@163.com

dinys009@163.com